Posted on: Tuesday, January 28, 2025

At Goldex, the journey of creating millions of pens every day is one of passion, technology, and dedication. Where pens might look simple to some, making a pen involves a careful process at each step for quality and reliability.

It all starts with procuring high-quality raw materials, such as durable plastic for the barrels and premium metals for the tips. Such materials are thoroughly inspected to make sure they meet our stringent requirements. Precise moulds shape the barrels, caps, and ink reservoirs of pens into their smooth and ergonomic shapes characteristic of Goldex.

Another key section of our manufacture is ink production. Every batch produced is carefully formulated for smooth flow, quick drying, and brilliant colours. Be it black ink for professionals or vibrant colours for creatives, every single drop of this ink is put through strict tests to ensure consistency.

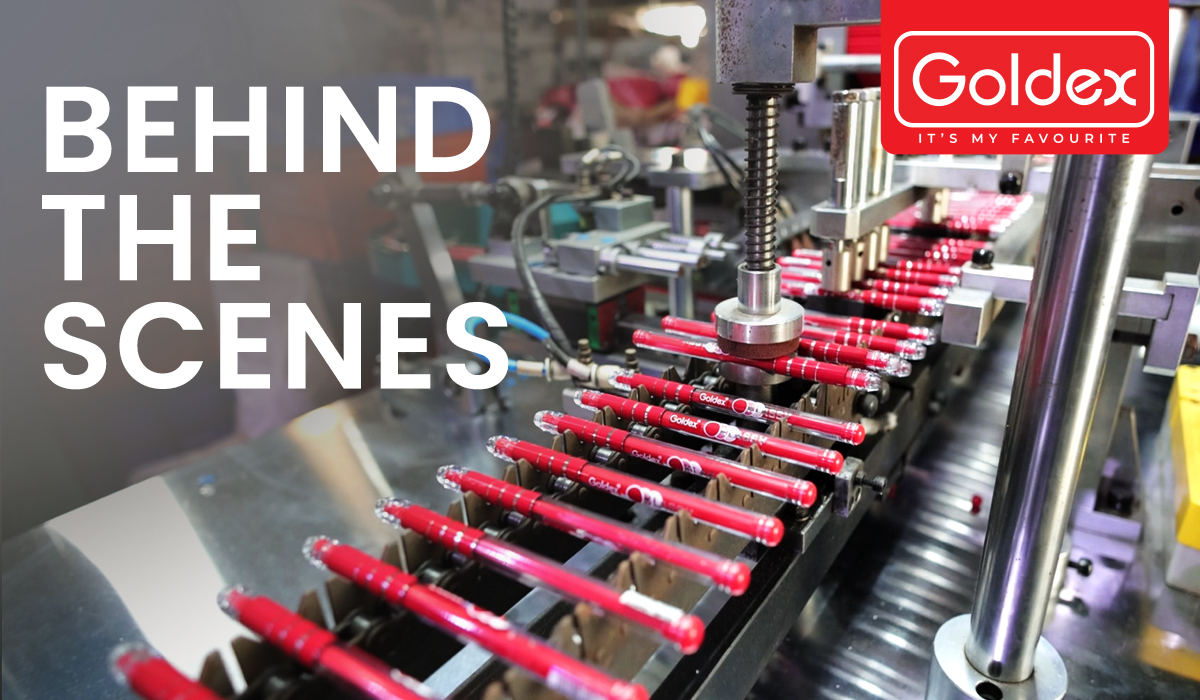

Once the components are ready, state-of-the-art automated machinery assembles them with incredible speed and accuracy. From inserting the ink reservoir into the barrel to attaching the clip and cap, every step is executed with precision. Our production lines are capable of producing millions of pens daily while maintaining uniformity and quality.

Quality control is paramount at Goldex. Each pen undergoes a series of tests to ensure it writes smoothly, feels comfortable in the hand, and meets customer expectations. Pens that pass these tests are packaged and prepared for shipment, ready to reach customers across India and the world.

Our behind-the-scenes operations are not just about efficiency; they’re about delivering writing instruments that inspire trust and creativity. Goldex’s ability to produce millions of pens daily without compromising quality is a testament to our commitment to excellence.

Every pen we craft is a symbol of innovation and passion, designed to make your writing experience seamless and enjoyable.